Make your own awesome radial engine fidget spinner, all you need is a 3D printer and a high speed bearing. The spinner can be printed in under an hour and the bearing just presses into the model afterwards. It’s super cheap and easy to make.

What You’ll Need To Make Your Own Radial Engine Fidget Spinner

- 3D Printer – Buy Here – Alternately Order Printed Part Online

- HIPS, ABS or PLA Filament – Buy Here

- 608 High Speed Bearing – 22mm OD, 8mm ID – Buy Here

- 9 M3 x 8 Socket Head Cap Screws (Optional To Add Weight) – Buy Here

- Spray Paint (Optional – If You Don’t Have The Right Filament Colour) – Buy Here

How To Make Your Own Radial Engine Fidget Spinner

Making this fidget spinner is super easy, all you need to do is 3D print the radial engine model and then install the high speed bearing. You can also add an optional machine screw into each cylinder head to increase its weight and speed.

3D Printing The Fidget Spinner Model

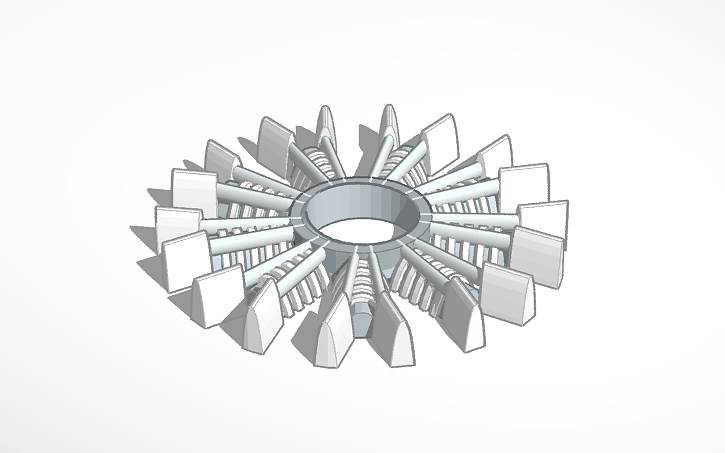

The model was designed in TinkerCAD, the STL file can be downloaded here – Radial Engine Fidget Spinner.

The fidget spinner model can be printed in any type of plastic filament. It was printed for this guide in both HIPS and PLA with the following temperatures and an infill of 30%.

HIPS

- Bed Temperature 95°C / 205°F

- Nozzle Temperature 225°C / 440°F

PLA

- Bed Temperature 40°C / 100°F

- Nozzle Temperature 205°C / 400°F

Here’s a time-lapse video of the print. It took around an hour to complete.

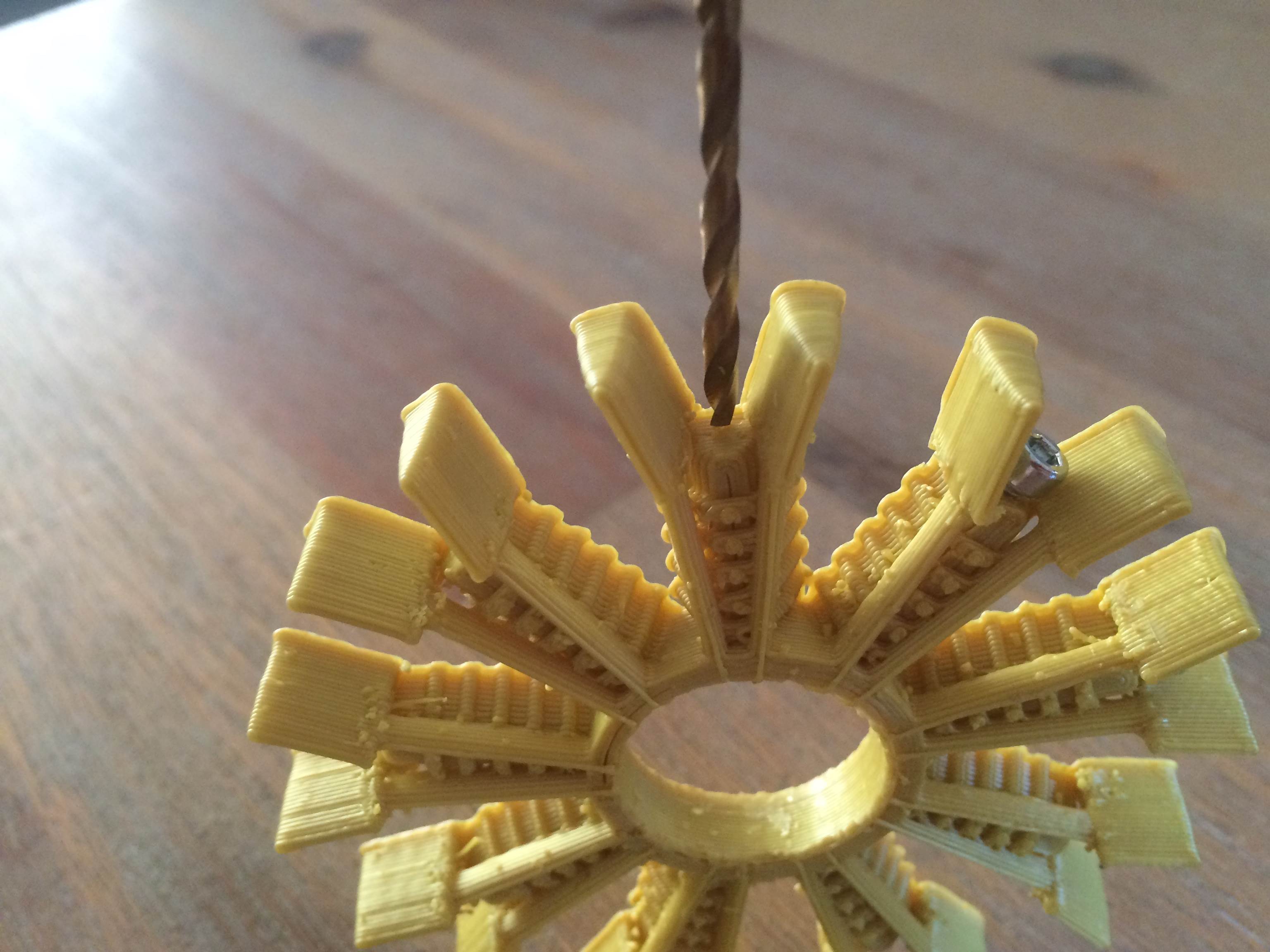

Adding Weight With Screws

In order to give the fidget spinner a longer spin time, it needs more weight. This can easily be added by installing a screw into the head of each piston. Drill a 3mm hole into the centre of each piston head, the hole only needs to be about 10mm deep.

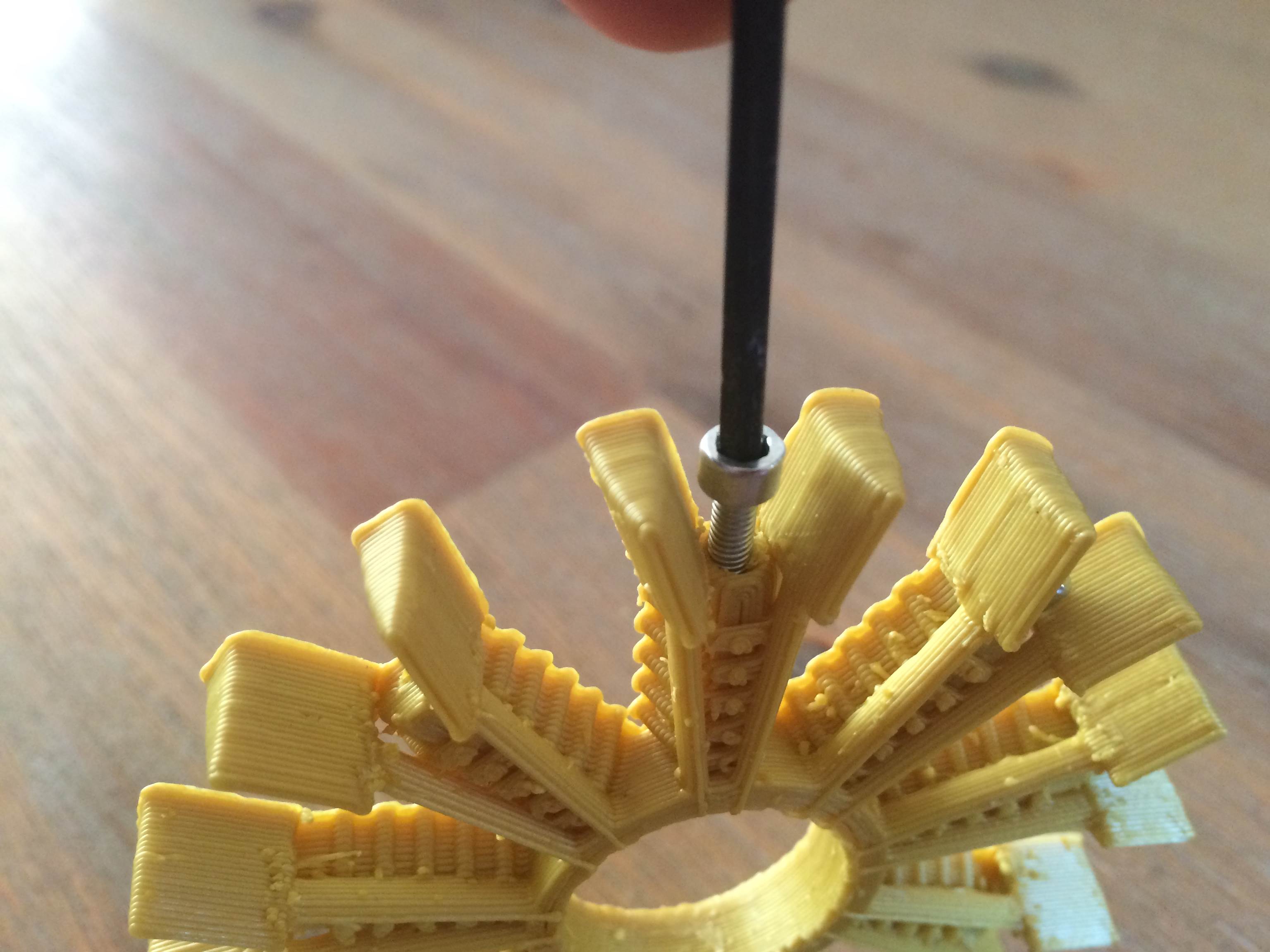

Screw a screw into each piston so that the head of the screw is almost flush with the top of the piston.

You’ll need to install one into each piston in order to keep the spinner balanced.

Adding The Bearing

The 608 bearing simply presses into the hole in the centre of the engine model.

Line the bearing up with the hole, place it onto a flat surface, bearing side down and then press the 3D printed model down onto the bearing. It should be quite a tight fit and should be squared up with the edges of the model.

Paint the Radial Engine Fidget Spinner

Lastly, you can paint the fidget spinner if you don’t have the colour filament you like. If you’re going to paint your spinner, do it before installing the bearing and screws or remove them before painting.

Place the plastic model face up on a sheet of newspaper and spray it as per the directions on your spray paint can.

Once the paint has dried completely, flip it over and paint the other side. It may require a few coats on each side to ensure coverage in all the gaps and ridges.

Re-install the screws and bearing and your spinner is ready to use. I’ve brushed some silver paint onto the fins on the pistons to highlight the edges.

Do you have any cool ideas for fidget spinners? Let us know in the comments section below, we’d love to see your ideas!